Automata Workshop

The completed animatronic piece can be seen here.

Making rollers.

I like using lignum vitae rollers on cam followers because this takes away a lot of friction from the piece. I used to turn them on the lathe from square sections but this is time consuming and wastes a lot of material. Now I use a plug cutter in the pillar drill. This cuts consistent rollers with highly polished surfaces. It is also very fast.

I like using lignum vitae rollers on cam followers because this takes away a lot of friction from the piece. I used to turn them on the lathe from square sections but this is time consuming and wastes a lot of material. Now I use a plug cutter in the pillar drill. This cuts consistent rollers with highly polished surfaces. It is also very fast.

The finished cam followers with the rollers fitted with brass axles.

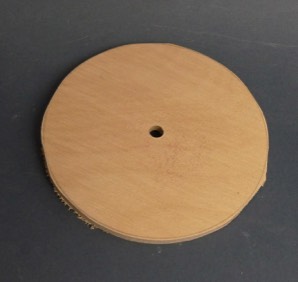

I need to tell the micro controller what the position of the axle is so that it can stop the motor when the men are either talking or staring. For this I use a disc with 2 holes with and LED shining through to a light sensitive resistor.

It looks best of the disc is a good circle so to best achieve this i rough cut the disc from birch ply on the band saw.

It looks best of the disc is a good circle so to best achieve this i rough cut the disc from birch ply on the band saw.

I then use the band sander to finish the circle to the line.

This gives a good finish.

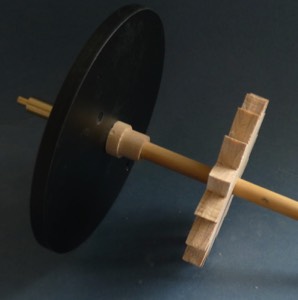

A small collar made on the milling machine will hod the disc at right angles to the cam shaft.

This could also be turned on the lathe but I wanted to try out the capabilities of my new mill.

This could also be turned on the lathe but I wanted to try out the capabilities of my new mill.

The finished and painted disc mounted on the cam shaft.